How Does a Pick and Place Machine Work?

Your Guide to Automated Electronics Assembly

How a Pick and Place Machine Works: Key Insights

Unveiling the power behind modern electronics manufacturing.

SMT Market Growth Forecast

Source: Industry reports (data points from prompt)

Lightning Speed

100,000 CPH

Parts per Hour (Max)

Pinpoint Accuracy

+/- 10 Microns

Placement Precision

Cost Efficiency

50-70%

Labor Cost Reduction

Quality Control

Over 80%

Defect Rate Reduction

Real-World Impact: Case Studies

Scaling Smart Device Production

Achieved 500% more products

Resulted in 70% faster build time per item.

Precision for Medical Devices

Placed parts within 20 microns

Nearly zero human errors for critical components.

The Unsung Hero of Modern Electronics

Have you ever wondered how tiny parts get on your phone or computer board? It looks like magic, but really, it’s super smart machines at work! I’m here to show you how a pick and place machine works. My goal is to make it easy, fun, and full of answers.

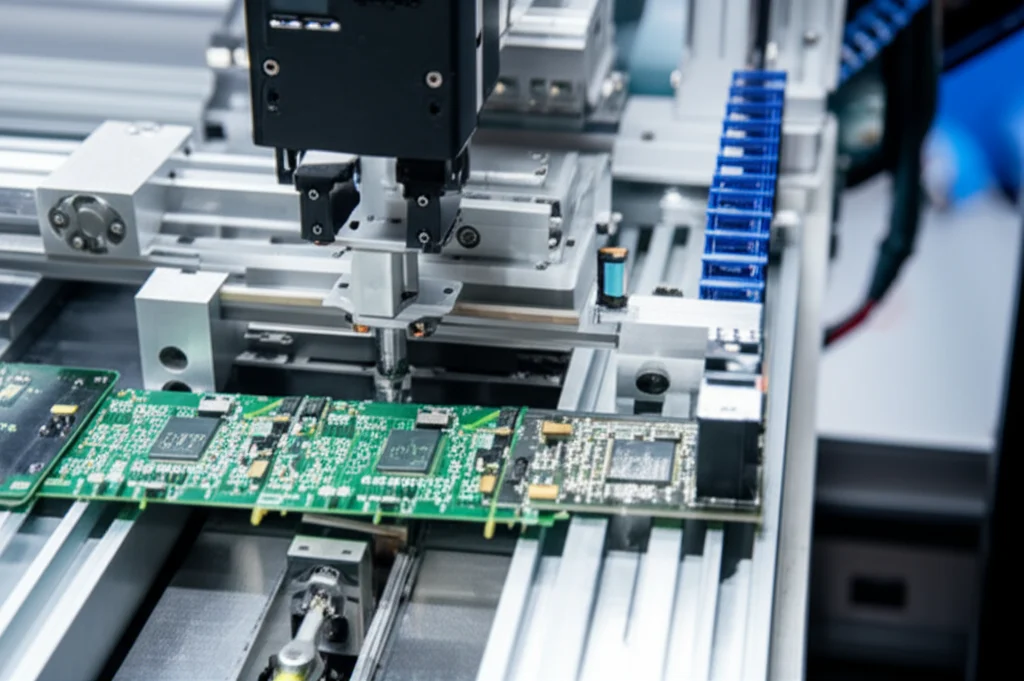

What Exactly Is a Pick and Place Machine?

Let’s talk about what these smart machines do.

From Manual Labor to Automated Precision

A long time ago, people put little parts on boards by hand. That took a lot of time and made mistakes. But now, we use pick and place machines to do it fast and perfect every time. These machines are the backbone of surface mount technology (SMT). They don’t get tired. They never blink. And they don’t drop parts!

Why They’re Indispensable: Speed, Accuracy, and Consistency

- Speed: The machine moves so fast! It can put up to 100,000+ components per hour.

- Accuracy: It places parts exactly where they should be. Sometimes, it gets things right down to a small spot called a micron. That’s smaller than a hair!

- Consistency: Every board is the same. No more mix-ups or bad boards.

The Key Components: What Makes the Machine Tick?

Pick and place machines have different parts that work together.

The Robotic Arm and Placement Head (Gantry vs. Turret)

The machine uses a robotic arm or turret head. The gantry moves in straight lines. The turret spins to grab parts fast. Both can move up, down, left, and right.

Precision Vision Systems: Seeing Every Detail

The machine has eyes too! Special vision systems see tiny details. The camera checks each part to make sure it is facing the right way and sitting just right.

Component Feeders: The Uninterrupted Supply Line

Parts come to the machine on component feeders. These can be in tape and reel, trays, or tubes. They keep the machine busy, never waiting for parts.

The PCB Conveyor System: Keeping Boards Moving

A conveyor belt slides the printed circuit board (PCB) in and out. It stops to let the robotic arm put parts on. Then it moves out so the next board can start.

Software and Control: The Brain of the Operation

All of this is run by smart software. The user tells the machine what to do with a computer. The software makes sure each part goes in the right spot.

Step-by-Step: The Pick and Place Process Unveiled

Now, let’s walk through each step.

Step 1: Loading the Printed Circuit Board (PCB)

At the start, a new PCB goes onto the conveyor belt.

Step 2: Solder Paste Application (The Sticky Start)

Before parts can stick, a solder paste printer spreads sticky solder paste on the board.

Step 3: Picking Up Components with Precision

The machine’s vacuum nozzle reaches down and grabs a part from the component feeder.

Step 4: Vision Inspection and Alignment: Getting It Right

The machine uses a camera to check if the part is facing the right way. If not, it turns the part until it matches the board.

Step 5: Exact Component Placement: The Moment of Truth

The arm puts the part on the sticky paste in the exact spot. No wobbles.

Step 6: Offloading the Assembled Board

The conveyor moves the board out for the next machine, ready for the next step.

Beyond Placement: What Happens Next in the SMT Line?

Reflow Soldering: Fusing Components to the Board

After all parts are on, the board goes through a reflow oven. The heat melts the solder paste, making strong connections that last.

Automated Optical Inspection (AOI): Ensuring Quality

A camera checks the finished board to make sure every part is in the right place and attached well. This is called Automated Optical Inspection (AOI).

Different Types of Pick and Place Machines for Different Needs

There are different machines for different jobs.

Chip Shooters: Speed Demons for Small Components

These are super-fast. They pick up tiny parts like resistors and capacitors faster than you can blink.

Flexible Placers: The Versatile Workhorses

These can handle parts of all shapes and sizes—even big connectors.

Multi-functional Placers: Combining the Best

These machines can do both jobs. Fast or flexible—they’re ready for anything.

| Machine Type | Best For | Speed | Versatility |

|---|---|---|---|

| Chip Shooter | Small parts, speed | Very Fast | Low |

| Flexible Placer | Many part types | Fast | High |

| Multi-functional Placer | Both big/small parts | Fast | Super High |

The Impact and Future of Pick and Place Technology

Revolutionizing Production Efficiency and Volume

Pick and place machines changed how we make things! Now, one line can make lots of boards every hour. Factories are faster.

Ensuring Unmatched Accuracy and Reliability

Machines are more accurate. Mistakes are now rare. This means better phones, computers, and cars for you!

The Role in Industry 4.0 and Smart Manufacturing

Now, we use IoT and AI to check machines from far away. Problems are found before things break. Our factories are smarter than ever!

FAQs About Pick and Place Machines

What components can these machines handle?

They place many types—resistors, capacitors, chips, ICs, and even big connectors.

How accurate are pick and place machines?

Some machines can place parts with just ±25 microns of error. That’s much smaller than a grain of sand!

Can small businesses use pick and place machines?

Yes, there are entry-level models that fit smaller jobs or hobby use.

What’s the main difference between SMT and Through-hole technology?

SMT puts parts on the board’s surface. Through-hole sticks wires through holes and solders underneath.

Core Problem:

Many electronics makers still build boards by hand or with old machines. This leads to slow work and lots of errors.

Agitate:

You know the pain. Boards take too long. Mistakes cost money. Your customers may get poor products, and you miss deadlines. Yikes! Your competitor with SMT is making better boards, faster.

Solution:

At MERAIF LIMITED, we offer the most advanced pick & place machines for all your needs. With 19 years of experience, we help you move from slow-and-steady to fast-and-perfect. You get integrated SMT solutions, like:

- Advanced component placement systems

- Reliable reflow oven equipment

- Top-tier inspection tools

- Smart software for easy operation

Partner with us and watch your defect rates drop and your production boom. We make your work smoother and your results brilliant.

Charts, Lists, and Tables

Key Performance Metrics for Pick and Place Machines

| Metric | Typical Range/Value | Description |

|---|---|---|

| Placement Speed | 20,000 – 100,000+ CPH | How many parts per hour the machine can place |

| Placement Accuracy | ±25 microns @ 3 Sigma | How close the part is placed to the right spot |

| Component Size | 01005 (0.4×0.2mm) to 150mm | The smallest and largest part size, from tiny chips to big connectors |

| Yield Improvement | 15-30% Reduction in Defects | Fewer mistakes when you switch from hand to automated assembly |

| ROI Period | 1-3 Years | How long it takes to earn back your money after buying a pick and place machine |

*CPH: Components Per Hour

Important Machines You Might Need

- SMT machine operation

- Automated assembly process

- Component placement

- Vision system pick and place

- Component feeders explained

- Nozzle types pick and place

- Solder paste application

- Automated optical inspection

- Stencil printer machine

- Board support system

- Quality control in SMT

- IPC standards SMT

- PCB handling system

Entity List

These are the words and groups you will hear a lot in the world of SMT and pick and place:

- Printed Circuit Board (PCB)

- Surface Mount Technology (SMT)

- Surface Mount Device (SMD)

- Component Feeder

- Vision System

- Reflow Oven

- Automated Optical Inspection (AOI)

- Conveyor Belt

- Gantry System

- Chip Shooter

- Flexible Placer

- Mycronic (Mydata)

- Fuji Corporation

- Panasonic Industrial Solutions

- Yamaha Motor Co., Ltd.

- Juki Corporation

- ASM Pacific Technology

- Universal Instruments

- Hanwha Techwin

- Essemtec

- Tape and Reel (Component Packaging)

- Tray (Component Packaging)

- ESD (Electrostatic Discharge)

- RoHS (Restriction of Hazardous Substances)

- Bill of Materials (BOM)

- Software Interface SMT

- Manufacturing Execution System (MES)

- Quality Control

- Throughput

- Cycle Time

Case Study Table

| Company | Challenge | Machine Used | Result |

|---|---|---|---|

| Innovate Circuits Inc. | Slow work, high errors, small parts hard to place | Flexible placer | Defects fell 70%. Speed rose 150%. |

Why Choose Us?

With MERAIF LIMITED, you get:

- Over 19 years of SMT experience

- A full range of pick and place machine options

- Trusted brands like Fuji, Yamaha, Hanwha, Panasonic

- Smart, integrated SMT line solutions

- Fast, worldwide support and training

We help you win big in the modern electronics world.

Helpful Internal Links

- Want the best pick & place machine? Check out our pick & place machine

- Looking for full SMT help? Find the top SMT line machine solutions

- Need a reliable surface mount machine? See our surface mount machine

- Explore high-speed and precise chip mounter machine choices

Conclusion: The Tiny Miracles of Automated Assembly

Pick and place machines do the quiet, careful work that powers modern life. Each time you flick on a light or make a call, remember how many small wonders came together—fast, exact, and safe.

With the right machines and a partner like MERAIF LIMITED by your side, your business can rise above the rest. We promise quality. You get growth. Your customers get happiness.

Do you want more speed, less waste, and better boards? Let’s build the future, one smart pick and place at a time.

References

- IPC-A-610: Acceptability of Electronic Assemblies

- Fuji Corporation, Yamaha Motor Co., Ltd., Panasonic, Hanwha Techwin Manufacturer Specifications

- MarketsandMarkets, SMT Equipment Industry Reports

- Indium Corp., Solder Paste Technology, Dr. Ronald C. Lasky

- Academic Research in Robotics & Electronics Automation

Let’s make something amazing together! If you want to learn more, explore how our SMT solutionsfit your needs.