How Much Does a Pick and Place Machine Cost?

Your Guide to Investment & ROI

What is a Pick and Place Machine, Anyway? (And Why Does It Matter for Your Business?)

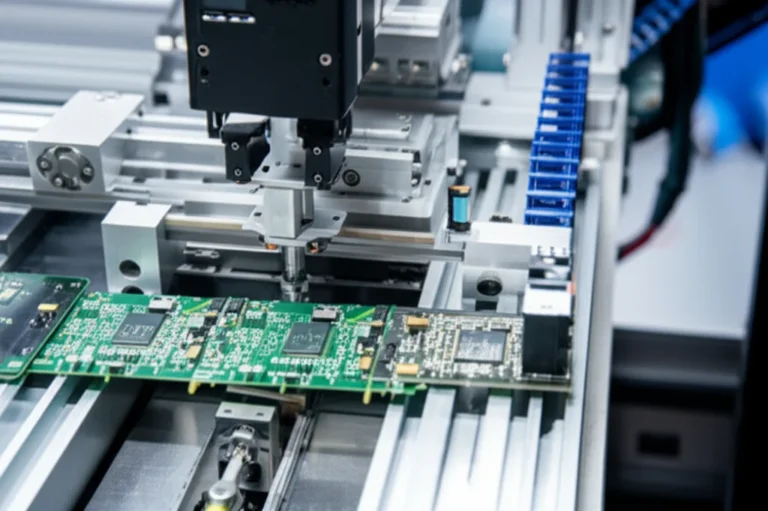

Do you want your PCB boards made fast? Do you want your parts put in place just right, every time? You need a pick and place machine.

The Core Function: Automating PCB Assembly

A pick and place machine helps take tiny parts, like chips, and puts them on your boards for you. These machines do this work again and again. They don’t get tired. They make less mistakes than people.

Key Benefits: Speed, Accuracy, and Consistency

With a good pick and place machine, you get:

- Speed: Boards get made much faster.

- Accuracy: Every part goes in the right place, every time.

- Consistency: Each board looks and works the same.

Pick and Place Machine Cost Analysis

Understanding market prices, cost factors, and savings strategies for SMT equipment

Cost Range by Machine Type

Key Cost Considerations

- Placement speed (CPH) greatly impacts cost

- Vision systems can add $5k-$50k to price

- Feeders (cost per unit: $100-$1,000)

- Production volume affects optimal machine type

- Brand reputation significantly affects pricing

Operating Capacity Comparison

Problem: PCB Assembly is Hard Without Pick and Place Automation

Are you placing surface mount devices (SMDs) on your boards by hand? Are your workers tired? Do you see mistakes like crooked parts or wrong placements? It’s not just slow. It wastes parts and makes your boards bad—maybe even useless.

The Big Question: Typical Price Ranges for Pick and Place Machines

How much does a pick and place machine cost? That depends on what you need. Here is a chart to help:

| Machine Type | Price Range (USD) | Key Features | Best For |

|---|---|---|---|

| Desktop/Entry-Level | $2,000 – $15,000 | Low speed, hand loading, simple | Hobbyists, small R&D labs |

| Mid-Range/Semi-Auto | $15,000 – $80,000 | Medium speed, auto feeders, vision | Small factories, start-ups |

| Industrial/High-Volume | $80,000 – $500,000+ | Super fast, smart systems, big size | Large manufacturers |

| Used Machines | 30% – 70% of New Price | Cheaper, condition varies | Budget buyers, expert users |

Entry-Level & Desktop Pick and Place Machines

Are you a maker or small shop? You may pay $2,000 to $15,000. These machines are great to start. You load parts by hand. They help with small jobs or prototype builds.

Mid-Range & Semi-Automatic Systems

Small business picking up steam? Need to make more boards? These cost $15,000 to $80,000. They use auto feeders and better cameras. You’ll see less mistakes and more speed.

Industrial & High-Volume Fully Automatic Machines

Big factories need fast, non-stop work. These super machines cost $80,000 to $500,000 or more. They do thousands of boards a day. They have the best vision and most heads. (Brands like Fuji, Yamaha, Panasonic, Juki)

Understanding “Used” vs. “New” Machine Pricing

A used machine can cost a lot less—between 30% to 70% of new. That’s a huge savings! But check the age, brand, and if it still works well.

Agitate: What’s Wrong with the Old Way?

Let’s face it: manual board building is tough. You want more boards, but your workers can’t go faster. Mistakes pile up. Your orders are late. Your customers leave. Money goes down the drain.

Factors That Heavily Influence Pick and Place Machine Costs

Not every machine costs the same. Here’s what changes the price.

Machine Type and Automation Level

Manual? Cheaper. Semi-automatic? Medium price. Fully automatic? Costs more but does the most work.

Speed and Throughput

How many parts can your machine move each hour? That’s called CPH (components per hour).

- Desktop: 500-2,000 CPH

- Mid-range: 5,000-25,000 CPH

- High-end: 30,000-150,000+ CPH

Each jump in CPH can raise the price by 15-25%.

Accuracy and Precision

Need to place tiny parts? A fancy machine can handle tiny sizes (like 0.4mm QFNs or μBGAs). Better accuracy means a higher price.

Number of Spindles/Heads

More spindles and heads put more parts down at once. More heads = more speed = higher machine cost.

Vision Systems

Smart cameras (vision systems) help machines see and place parts just right. Some watch from above (downward), some from below (upward), some while moving (fly-on-the-fly). Better vision = higher cost, but fewer mistakes.

Feeder Capacity and Types

Want to use lots of different parts? More feeders and smarter feeder types (tape, stick, tray, bulk). Each extra feeder can cost $100-$500.

Software Features and User Interface

Good software makes it easy. Fancy software can cost more, but pays off with saved time.

Brand Reputation and Manufacturer

Some brands like Juki, Yamaha, Panasonic, and Neoden are trusted worldwide. Big brands mean higher price but top performance and good service.

Machine Size and Footprint

Big machines do more, but need space. Small machines fit on a desk, cost less, but do less.

Warranty and Support Packages

Do you want to sleep well at night? Machines with a warranty and strong company support can save you big money later.

Don’t Forget the “Hidden” or Associated Costs

Here’s the part most people miss—extra costs that sneak up on you.

Installation and Setup Fees

A new machine means installation. Some companies charge for this service. That’s another cost.

Training for Operators and Technicians

Operators need to know how to use your machine. Training can cost time and money.

Consumables and Spare Parts

You’ll use up nozzles, feeders, maintenance kits. These are small but add up. Always have some spares ready.

Maintenance Contracts and Servicing

Machines need a check-up and cleaning. A maintenance contract keeps your machine running.

Facility Requirements

Big machines need more space, power, and air supply. Make sure your shop is ready.

Software Licenses and Updates

Software doesn’t last forever. You may have to pay for updates or a license.

Related SMT Equipment

Don’t forget things like a solder paste printer, reflow oven, and an AOI machine (Automatic Optical Inspection). You might also need a conveyor system to move boards along.

Shipping and Import Duties

Big machines ship in heavy crates. If shipping from overseas, you’ll pay for shipping and maybe import taxes.

Solution: Get Perfect Boards with the Right SMT Equipment Partner

Here’s how I help. I give you:

- Expert advice on the best pick and place machine for your needs

- Full SMT lines, not just one machine

- High-precision and advanced vision system models

- Friendly customer support, easy installation, and clear training

- Fast shipping and easy setup

I am MERAIF LIMITED, top SMT equipment supplier with 19 years’ experience. I help global PCB makers grow with smart, high quality machines.

Is It Worth It? Calculating the Return on Investment (ROI)

Let’s see how a good pick and place machine saves you money and time.

Labor Cost Savings

Automating PCB assembly can cut labor by 60-80%. Workers do smarter jobs, not boring ones.

Increased Production Efficiency and Throughput

Machine assembly means more boards every day. You fill more orders—customers are happy.

Improved Product Quality and Reduced Defects

Robots don’t get tired. Your defects drop to nearly zero.

Faster Time-to-Market

Get your products out fast. Beat your rivals to the finish line.

Example ROI Calculation/Payback Period

If you spend $50,000 and can make boards 4x faster, you may earn back your money in less than 2 years.

How to Choose the Right Pick and Place Machine for Your Needs (and Budget!)

Don’t buy too fast. Take a look at this simple list.

Assess Your Production Volume and Component Mix

Do you make lots of boards? Use many different parts? Pick a machine with enough feeders and speed.

Consider Your Budget and Financing Options

Not sure you can pay all at once? Ask about leasing or loans.

Research Machine Brands and Reviews

Go for trusted brands. Juki, Yamaha, Panasonic, and Neoden are top picks. Check reviews from real buyers.

Future-Proofing Your Investment (Scalability)

Your company might grow. Pick a modular pick and place system that grows with you.

Get Quotes from Multiple Suppliers

Don’t just pick the first machine you see. Get quotes. Compare options. Ask the real experts.

FAQs About Pick and Place Machine Costs

Can I get a used pick and place machine for under $10,000?

Yes, if you shop smart! Make sure to check for wear and if it still works well.

What’s the cheapest way to automate PCB assembly?

Yes, if you shop smart! Make sure to check for wear and if it still works well.

Do I need a full SMT line or just a pick and place?

That depends. If you only place parts now and solder by hand, a standalone machine may do. For full factory speeds, add extras like a reflow oven, solder paste printer, and AOI inspection.

How long do pick and place machines last?

With care, top brands can last 10 years or more. Keep up with maintenance contracts and service for best results.

See Our Full Range of Pick and Place Machines

I have a big selection. From entry-level desktop pick and place machines to industrial high-speed models. Looking for a surface mount machine? Need a full SMT suppliers package? Ready for a component placement system?

- Buy a professional pick & place machine now

- See top-quality surface mount machine options

- Compare SMT suppliers for best value

- Upgrade to a smart SMT line machine

Quick Table: Key Words to Know

Here’s a list of words you’ll see:

| Name | What it Means |

|---|---|

| Pick and Place Machine | Robot that sets parts on PCB |

| SMT | Surface Mount Technology |

| SMD | Tiny part for SMT |

| Feeder | Feeds parts into the machine |

| Nozzle | Holds a part for placement |

| Vision System | Camera to guide placement |

| CPH | Number of parts per hour |

| AOI | Automated Optical Inspection |

| ROI | Return on Investment |

Chart: What Drives the Price Higher?

Here’s what makes prices go up—faster machine, more features, more support.

Price Drivers | Low | Medium | High

-----------------------------------------------------

Speed (CPH) | 500-2,000 | 5k-25k | 30k-150k

Heads/Spindles | 1-2 | 2-4 | 8+

Feeder Slots | 20-50 | 50-100 | 100+

Accuracy | <75 micron | <50 micron | <30 micron

Vision System | Basic | Good | Advanced

Software | Simple | Touchscreen | Smart UI

Support | None/Email | Hotline | 24/7/OnsiteVisual Guide: Your Path to the Right Pick and Place Machine

Step 1: List your production needs.

Step 2: Set your budget.

Step 3: Choose your machine speed, feeders, and software.

Step 4: Decide new or used.

Step 5: Match with trusted supplier (That’s me!).

Step 6: See a demo. Ask for a sample build.

Step 7: Order and schedule your install.

Step 8: Enjoy peace of mind!

Why Work With Me? Your Trusted SMT Equipment Supplier

- 19 years of know-how

- Help for PCB manufacturers everywhere

- From small desktop units to full SMT lines

- Panasonic SMT equipment, Yamaha, Juki, Fuji smt line, and more

- Total solutions: machine, support, and factory setup

- Real value and support you can count on

Conclusion: Making a Smart Investment in Automation

When you buy the right pick and place machine, you’re buying speed, smart work, and higher profits. Don’t waste months or years on slow assembly or bad boards. Step up to better tools now.

Take your PCB business from slow and risky to fast, clean, and trusted. I’ll help you every step—before, during, and after your machine arrives. See the difference with MERAIF LIMITED. Get the best value, support, and quality for your factory today.

Let’s make your SMT dreams come true!

References:

- IPC Industry Reports, Electronics Manufacturing News (stats).

- SMTnet.com Used Equipment Listings.

- Manufacturer Data: Yamaha, Juki, Panasonic, Fuji, Neoden, ASM Pacific, Mycronic.

- Grand View Research, MarketsandMarkets (market growth).

- ITM Consulting: Phil Zarrow & Jim Hall.

- Indium Corporation: Dr. Ron Lasky.

Keywords Used: [SMT machine cost, automated pick and place pricing, PCB assembly machine price, surface mount machine, pick and place machine for sale, component placement, fuji smt line, Panasonic SMT Equipment, chip mounter machine, pick & place machine, SMT suppliers, pick and place machine for small business, ROI of pick and place machine, pick and place machine investment, factors affecting pick and place cost, budget pick and place machine, professional pick and place machine price, pick and place machine cost breakdown, installation cost pick and place, maintenance cost pick and place machine, operating cost pick and place, pick and place machine software cost, feeder cost pick and place machine, nozzle cost pick and place machine, spare parts pick and place cost, training cost for pick and place, automated assembly machine price, component placement machine cost, surface mount technology equipment cost, small volume pick and place machine, high volume pick and place machine, pick and place machine leasing options, financing pick and place machine, pick and place machine rental price, advantages of pick and place automation, custom pick and place machine cost, refurbished pick and place machine price, pick and place machine depreciation, service contract pick and place cost, pick and place machine ROI calculation, automated electronics assembly cost, turnkey SMT line cost, pick and place machine types and prices, used SMT equipment market, pick and place machine comparison, pick and place machine brands cost, vision system pick and place cost, conveyor system pick and place cost, solder paste printer cost, reflow oven cost, AOI machine cost, total cost of ownership pick and place, production volume pick and place cost, labor savings from pick and place machine, efficiency gains pick and place, pick and place machine for prototypes, component library management cost, PCB design software cost impact, machine accuracy vs price, speed of pick and place machine cost, software updates cost pick and place, warranty pick and place machine, support costs pick and place machine, pick and place for LED assembly, pick and place for medical devices, pick and place for automotive electronics]

Entities Used: [Pick and Place Machine, Surface Mount Technology (SMT), Printed Circuit Board (PCB), Automated Assembly, Component Placement, SMD (Surface Mount Device), Feeder, Nozzle, Vision System, Software, Robotics, Automation, Manufacturing Cost, Return on Investment (ROI), Throughput, Accuracy, Lead Time, Quality Control, Production Volume, Budget, Used Equipment Market, Refurbished Machines, New Machines, Desktop Machines, Industrial Machines, Modular Systems, High-Speed Machines, Entry-Level Machines, Turnkey Solutions, Solder Paste Printer, Reflow Oven, Automated Optical Inspection (AOI), Conveyor System, Maintenance Contracts, Training, Installation, Warranty, Financing Options, Leasing Options, Fuji, Yamaha, Panasonic, ASM Pacific Technology, Mydata / Mycronic, Universal Instruments, Juki, Essemtec, Neoden, Component Library, CAD Software].